-

Diagnose how Magic Rack

will work for your warehouse - Start

diagnostics

News

-

November 1, 2024

We uploaded a new Magic Rack introduction video. -

April 21, 2021

Homepage renewed.

Magic Rack introduction videos

-

3min Quick Tour!

-

The Tale of Magic Rack ~Edo Logistics Innovation~

-

Video report at the Logis-Tech Tokyo 2024

-

Video report at the Logis-Tech Tokyo 2022

-

Video report at the INNOVATION EXPO

-

Basic structure and mechanism

-

Overwhelming storage capacity

-

Making full use of the limited height

-

Fits all kinds of buildings

-

Halved the building height

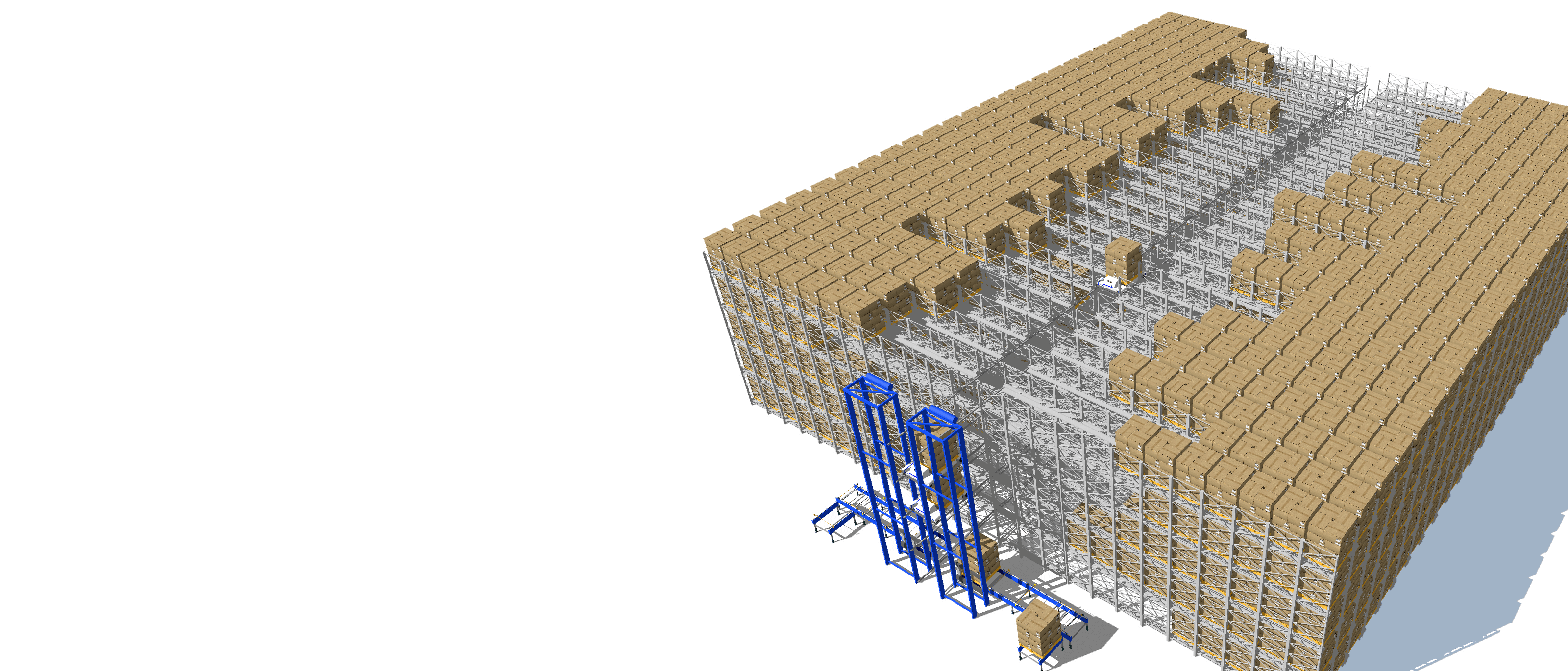

Features & Benefits of Magic Rack

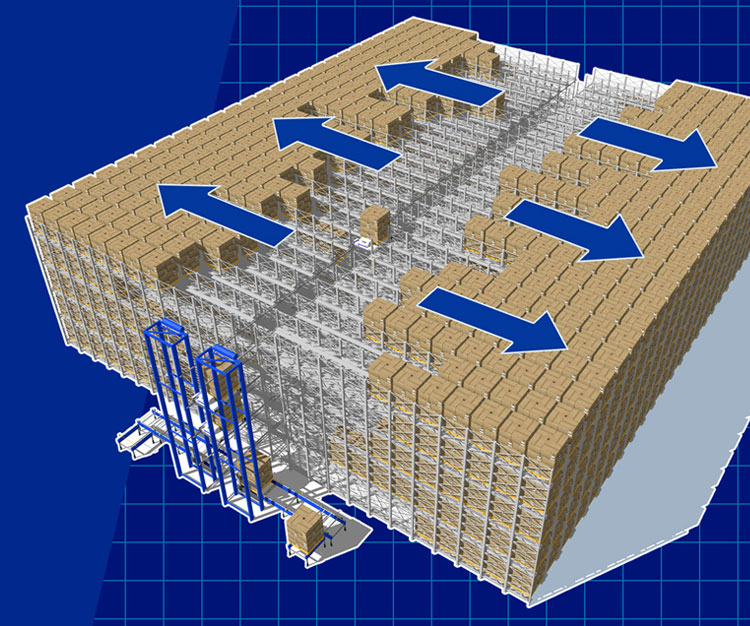

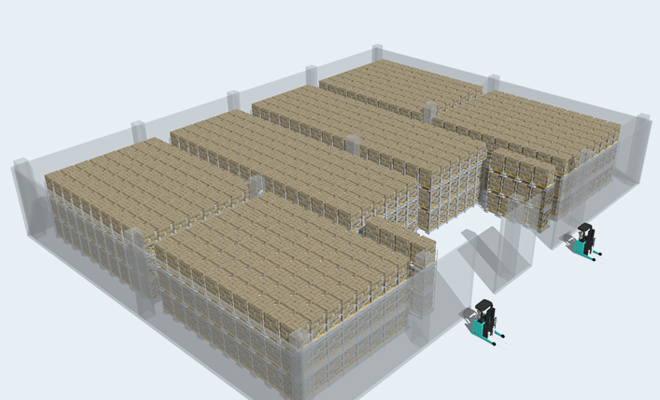

High density

- Deep Storage provides outstanding storage capacity

- Deep Storage carries multiple pallets to a single lane

and stores them along with minimal space in between.

It optimizes the use of limited space by achieving a high level

of storage efficiency that was not possible

with traditional storage methods.

-

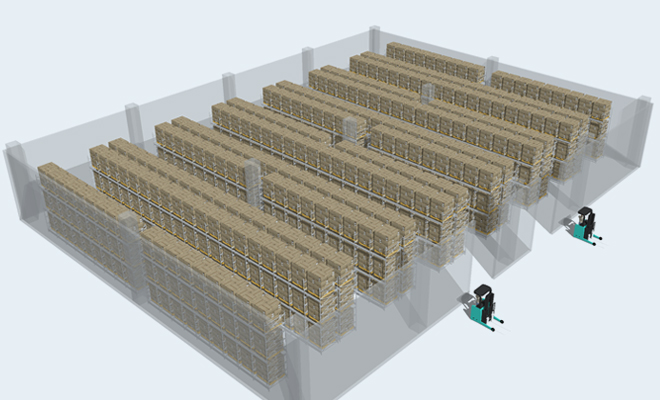

POINT 01

-

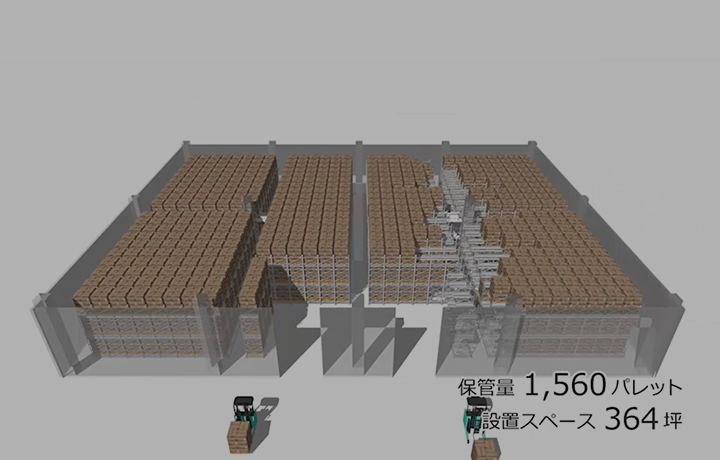

Double the amount of pallet storage

Magic Rack does not require forklift aisles.

It significantly increases the storage efficiency of your available space!

-

Traditional

- Traditional pallet rack

- Storage capacity: 780 pallets

(Installation space: about 1,200m2)

-

with Magic Rack

- Keep the same storage capacity in half the space

- Storage capacity: 780 pallets

(Installation space: 600m2)

-

with Magic Rack

- Double the storage capacity!

- Storage capacity: 1,560 pallets

(Installation space: 1,200m2)

-

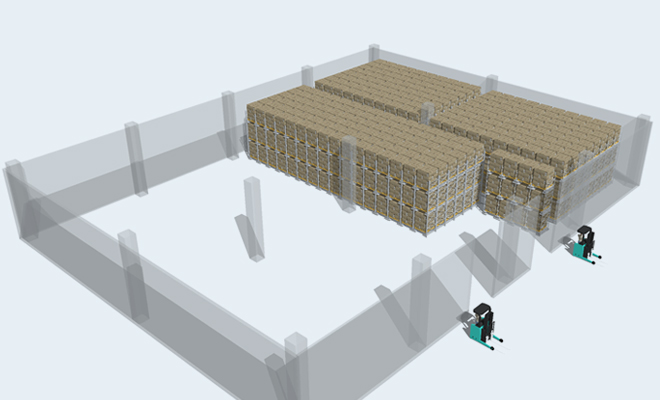

POINT 02

-

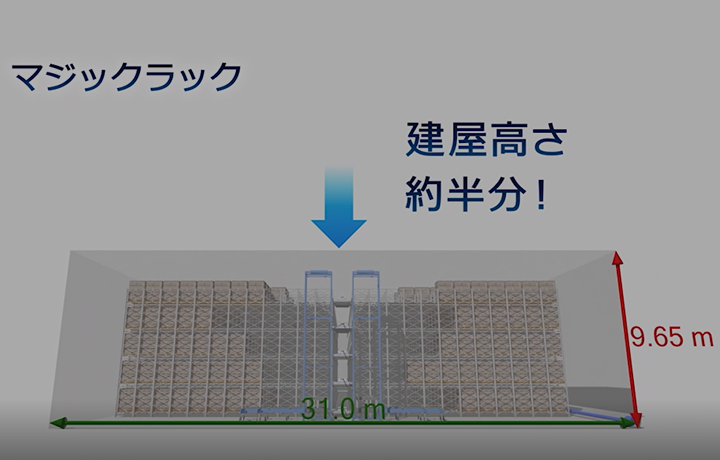

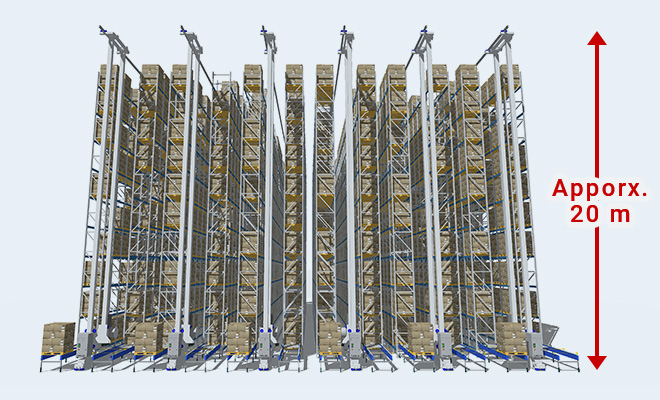

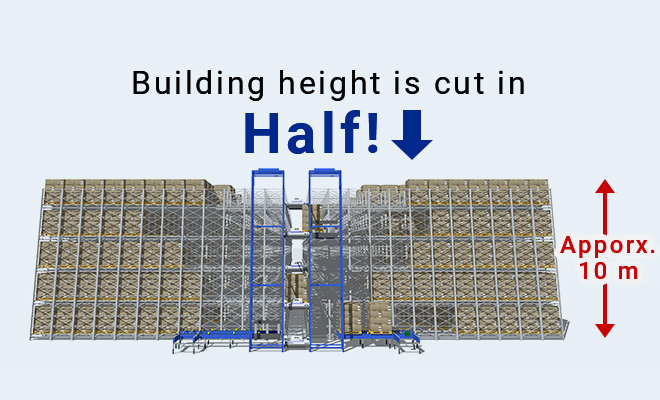

Halve the building height when constructing a new warehouse

With Magic Rack, when constructing a new warehouse, you can cut the building height in half compared to traditional stacker crane-type automated warehouses! Helps to reduce construction costs and materials.

-

Traditional

- Traditional automated warehouse

- * When pallet height is 1.5m

-

with Magic Rack

- Building height is halved!

- * In comparison with same number of pallets and floor space

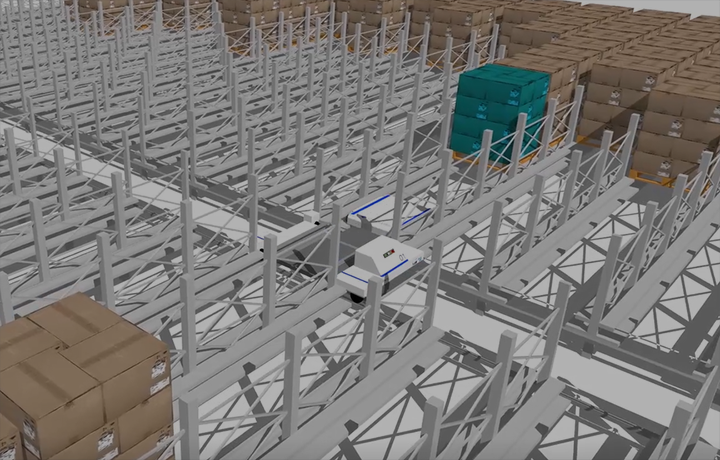

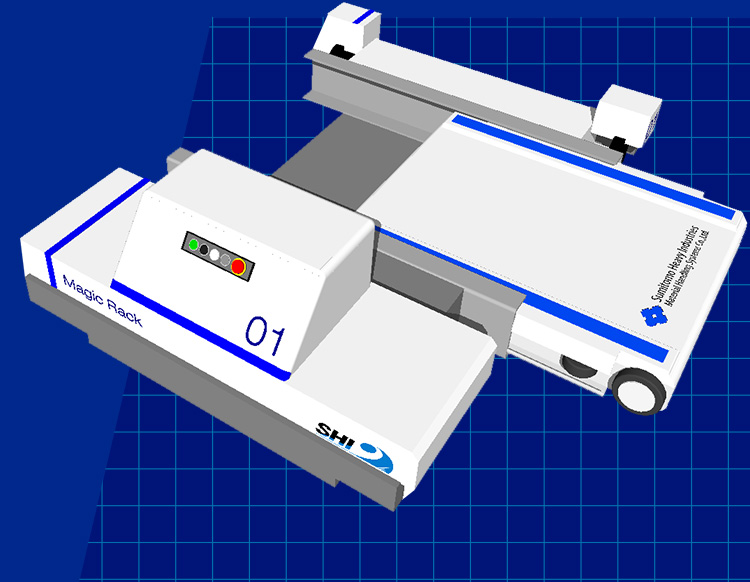

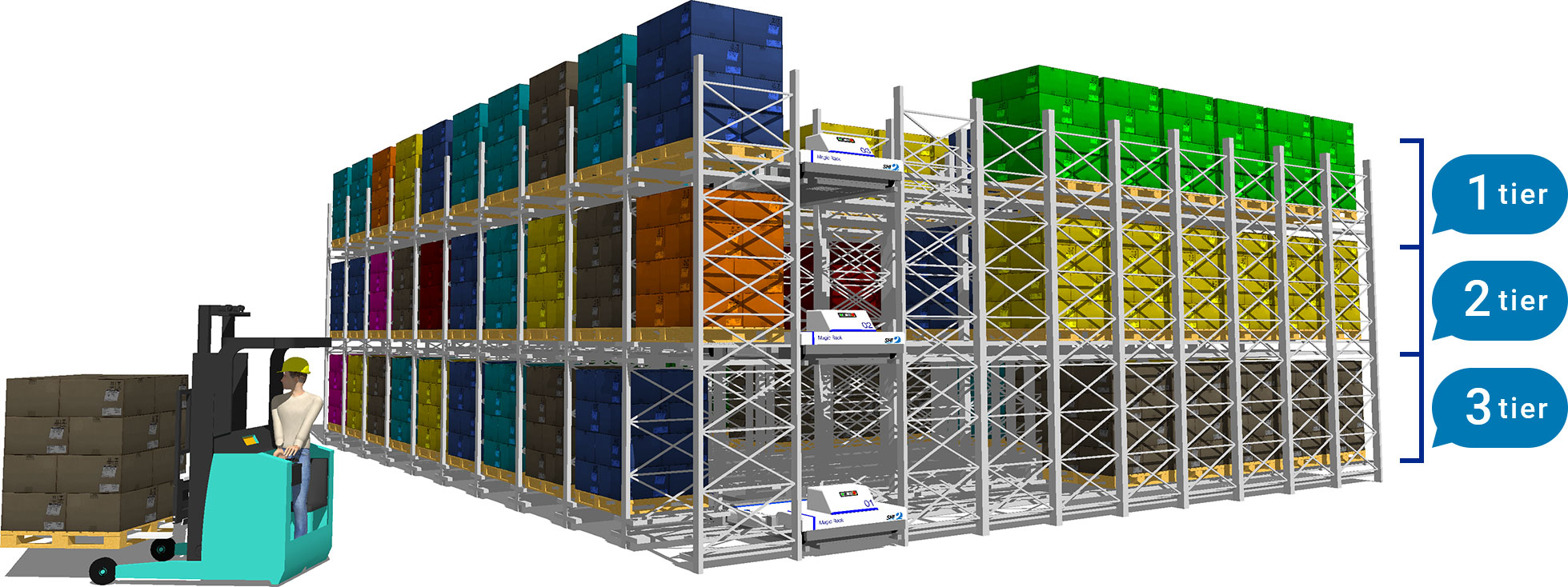

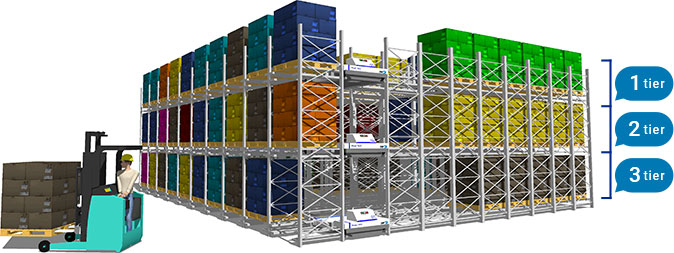

Automation

- Increase on-site efficiency

by saving labor on forklifts - Magic Rack is a system that automatically stores pallets

with unmanned carriers, the "Magic Dolly" and "Magic Shuttle,"

working in pairs. It delivers long-term cost reductions for logistics sites

by reducing forklift work in storage areas and carrying

out automatic warehousing/shipping and assorting 24 hours a day, every day.

-

POINT 01

-

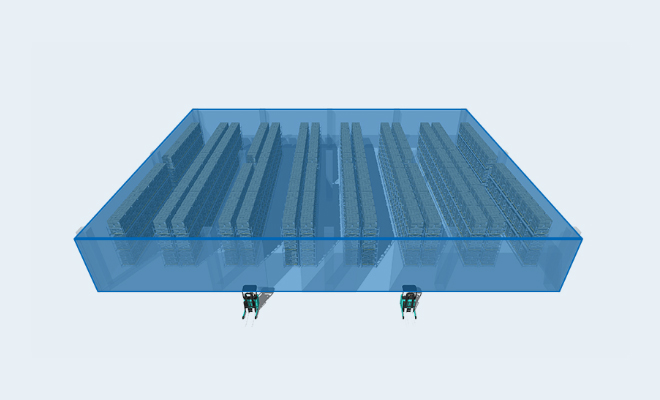

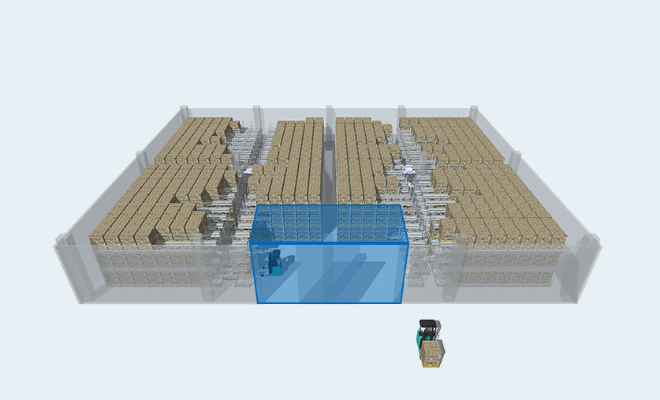

Minimized forklift work

Magic Rack automatically stores and retreives pallets with unmanned carriers, greatly reducing the forklift work area.

No more precious time wasted moving around warehouse for storing, retreiving and moving inventory.

-

Traditional

- Traditional automated warehouse

-

with Magic Rack

- Forklift work is done only near the access rack

-

POINT 02

-

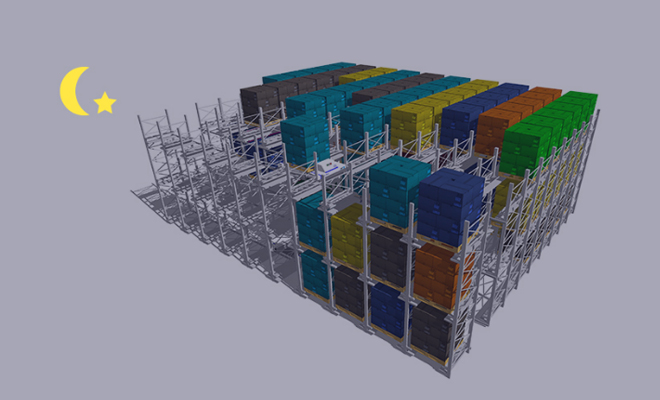

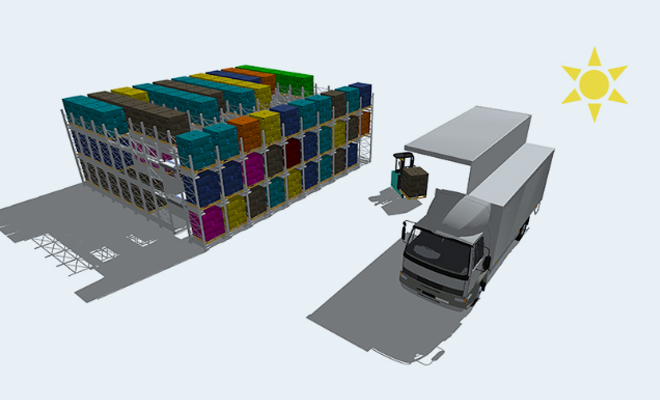

Smooth shipping with automatic sorting

Magic Rack can take advantage of the late-night hours when it is not in use to sort pallets in advance for the shipping of the following day.

The next day work can begin from the point where sorting is complete, reducing the truck wait time and forklift work.

-

with Magic Rack

- Automatically sorted overnight

-

with Magic Rack

- Next morning, just load!

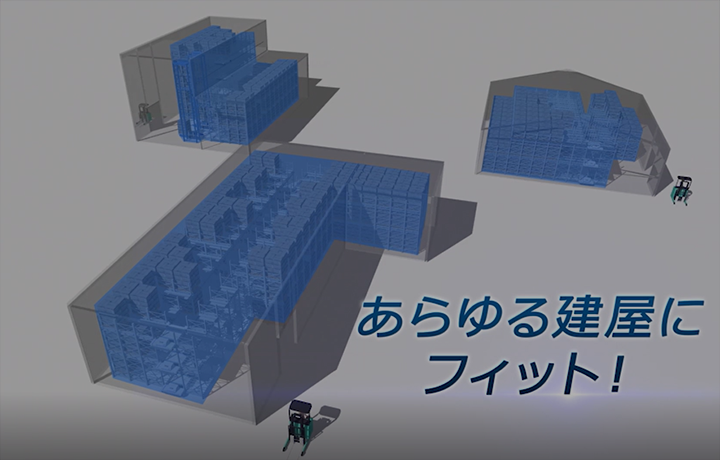

Flexibility

- Build optimum system for space

and operations at logistics sites - You can flexibly fit Magic Rack in buildings

and spaces that come in various shapes.

You can also coordinate Magic Rack

with various logistics systems in accordance

with your existing operations to create a optimized system.

-

POINT 01

-

Fits various building shapes

Magic Rack's layout is flexible, so you can make the most of buildings and spaces that come in various shapes.

-

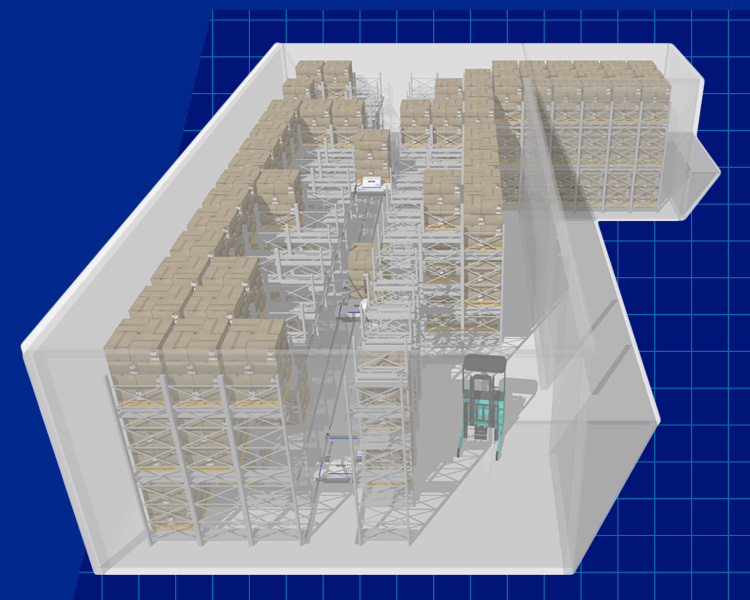

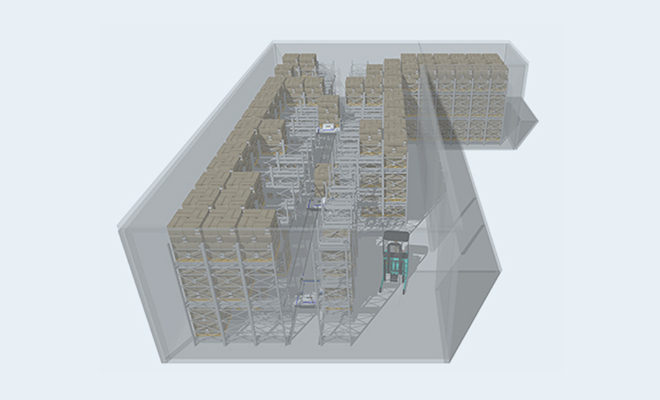

- L-shaped layout

-

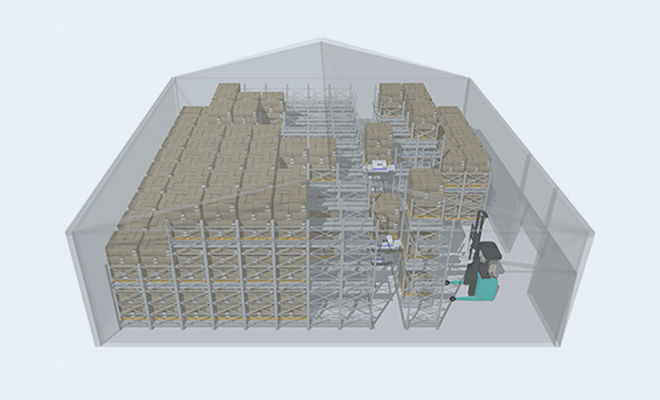

- Triangular ceiling

-

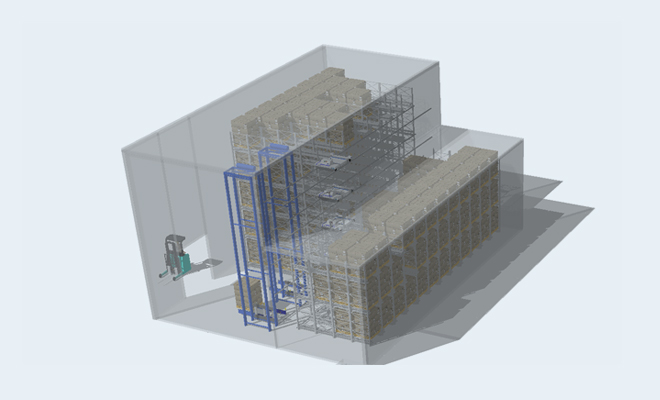

- Buildings with varying heights

-

POINT 02

-

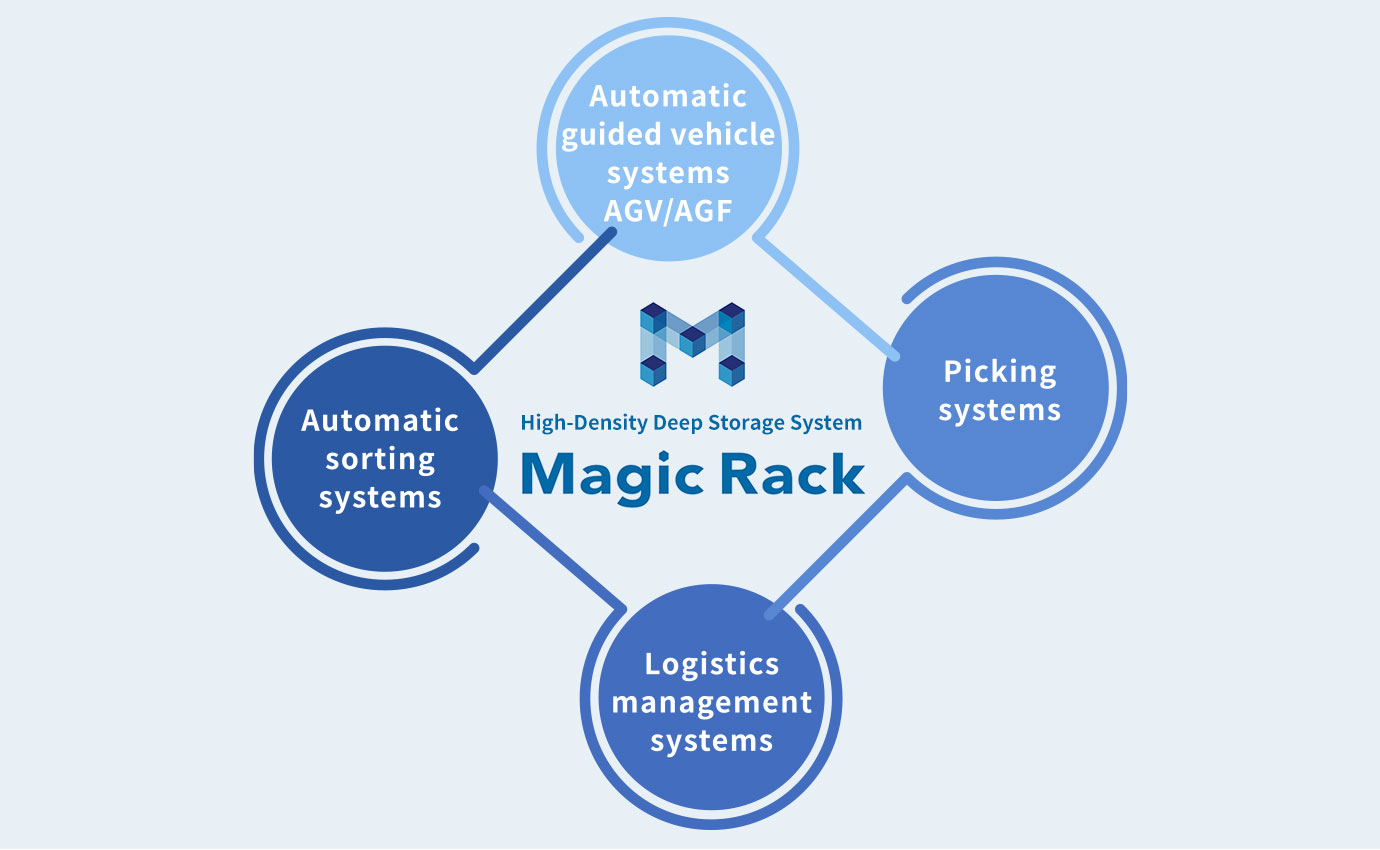

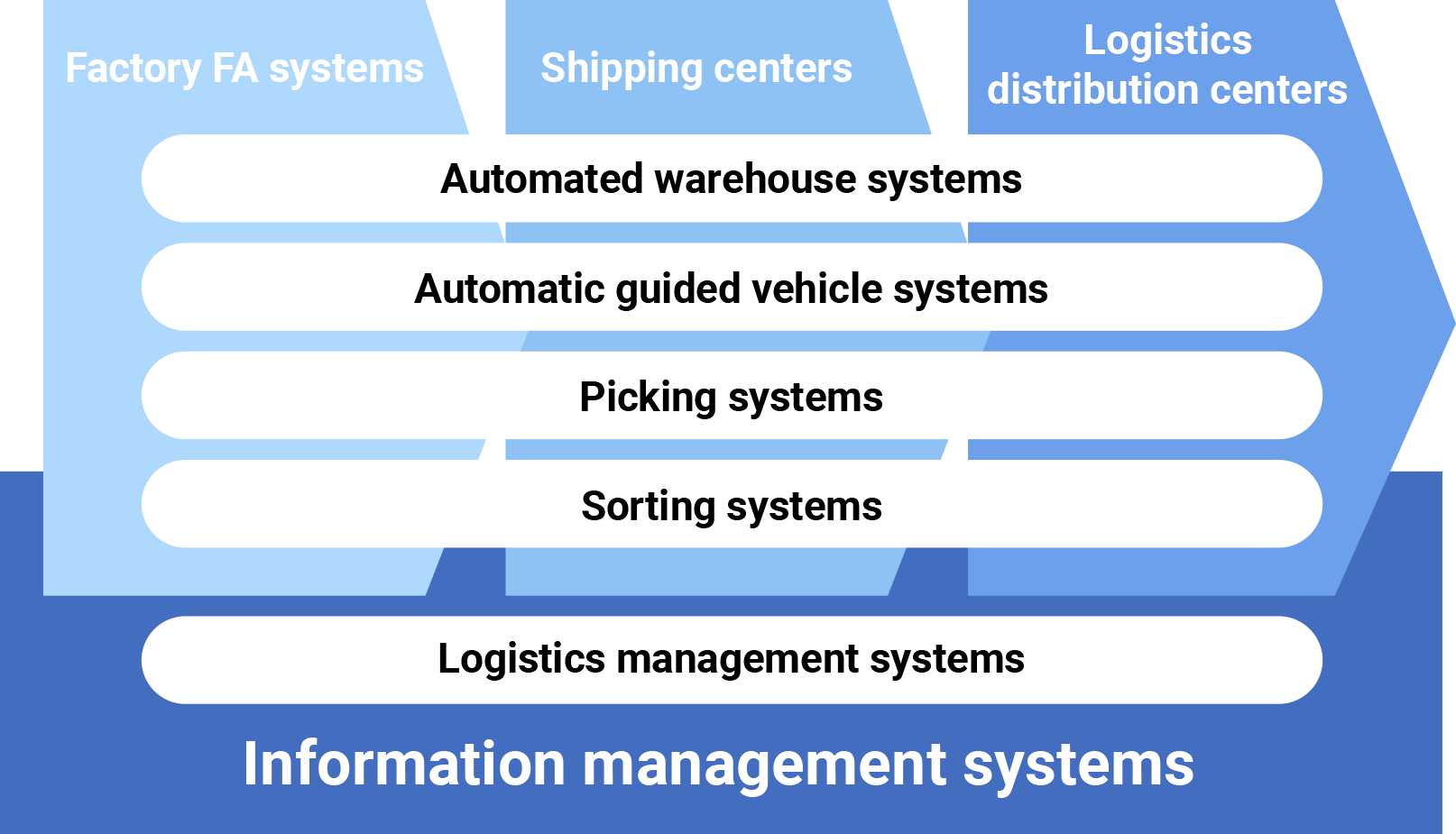

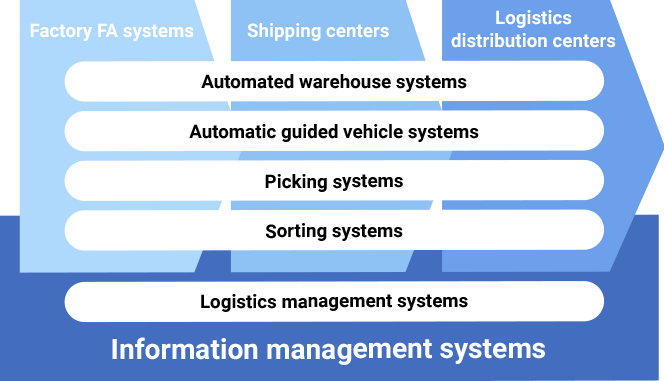

Coordinate with various logistics systems

Magic Rack can be coordinated with various logistics systems such as automatic guided vehicle systems (AGV/AGF), picking systems, and automatic sorting, depending on your operations, to provide an optimal solution.

-

- Magic Rack can be coordinated with various systems

Magic Rack installation/usage examples

Magic Rack with its high flexibility is suitable for the operation of various distribution centers,

depending on the equipment configuration and combination.

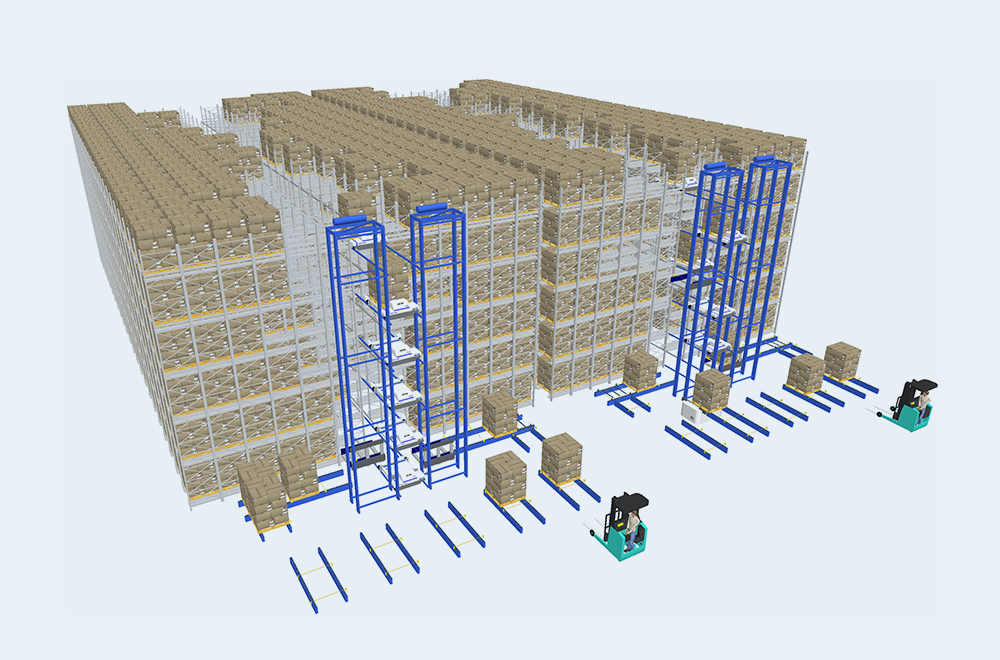

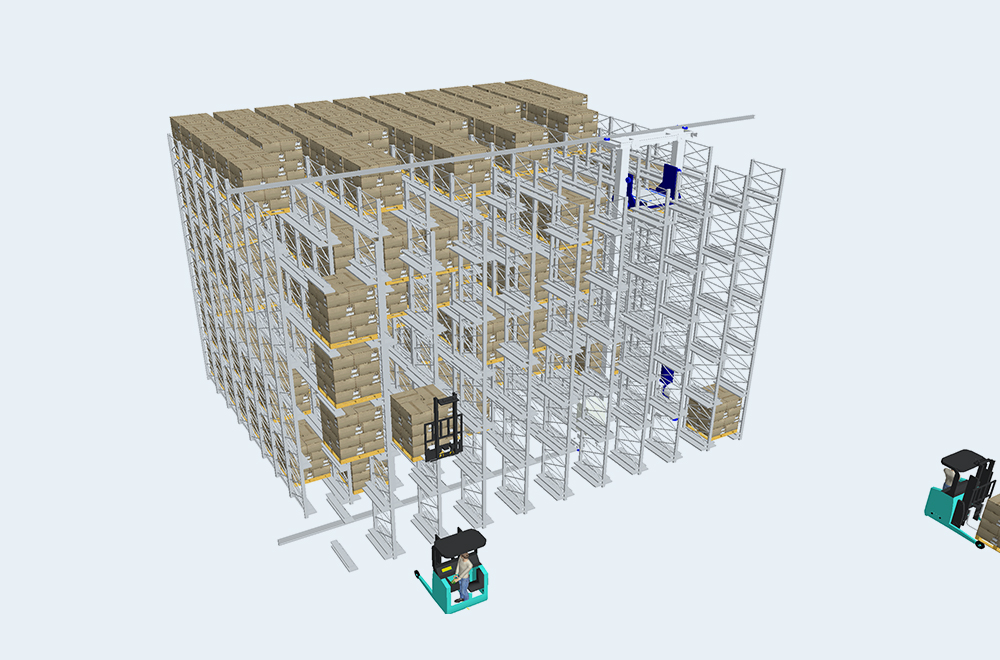

- Model for large-scale centers

- Lifter will automatize access to each tier. Prevents operational error and heavy forklift labor.

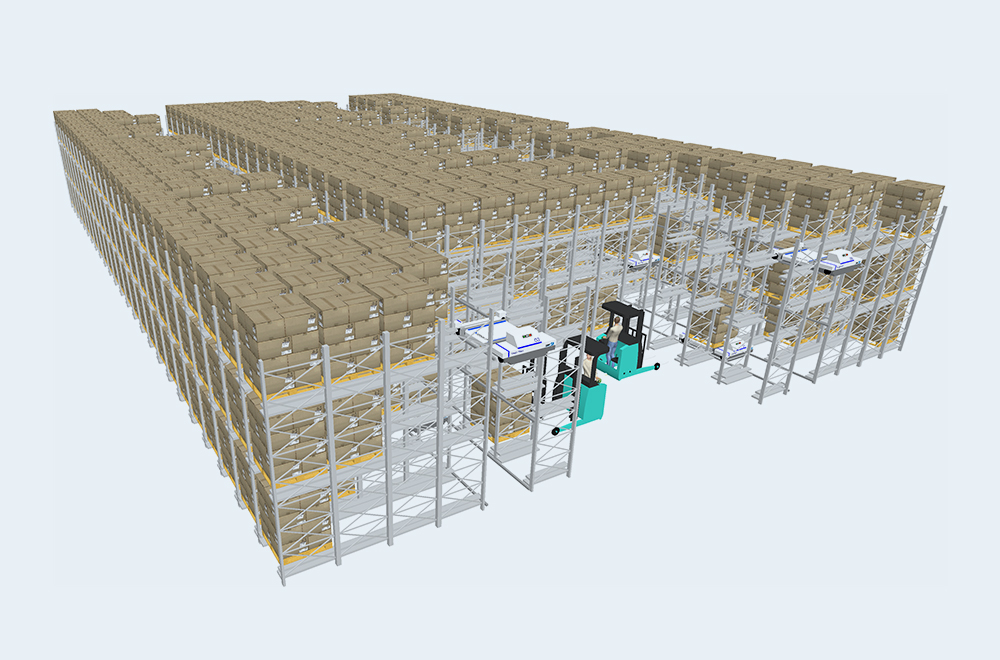

- Model for small- to medium-size centers

- Responds flexibly to storage and retrieval of high-mix low-volume products, while achieving high-density storage and labor savings

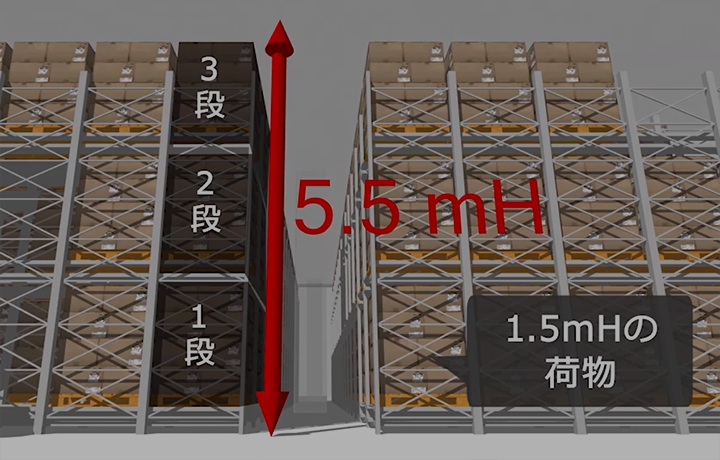

- Model for High-Bay storage

- Combination of stacker crane and Magic Rack will enable high-bay and high-density storage for limited space.

Magic Shuttle, with the world's slimmest design, will enable three-level storage for 1.5m height pallets in a warehouse with a 5.5m ceiling height.

* Required space varies depending on the specification.

Magic Rack case studies

-

Case Study

Overcomming multiple constraints in warehouse construction to achieved an overwhelming storage efficiency.

To expand shipping and supply to the Kanto area—the largest consumption area in Japan—food and beverage manufacturer A carried out a renovation project aimed at stepping up production and streamlining logistics...more

-

Case Study

Attempt to achieve automation and extreme high-density storage in a multi-floor warehouse where automation of pallet type material handling is not easy.

Various environmental changes are taking place at the logistics site due to changes in social structure. Particularly in Japan...more

Magic Rack implementation support

Sumitomo Heavy Industries Material Handling Systems offers optimal solutions for your logistic requirements,

based on expertise know-how developed through decades in the material handling business.

Magic Rack implementation flow

-

Contact us

If you are having problems with logistics or are interested in Magic Rack, please contact us.

-

Meeting and on-site survey

We will visit for a meeting to discuss your problems and survey your site.

-

Data analysis and simulation

We will create a detailed simulation to prepare a proposal by analyzing data obtained through the meeting and survey.

-

Solution proposal

We will create an optimal solution based on data analysis and simulation to solve your problems.

Sumitomo Heavy Industries Material Handling Systems' logistics system business

Supports business renovation at logistics sites as a manufacturer specializing in material handling

As a manufacturer that handles a wide range of materials, we offer optimal logistics systems for various business situations and locations, such as factory FA systems, and shipping centers, and wholesale distribution centers.

Logistics support for wide range of businesses and industries,

from factory FA systems to shipping/distribution centers

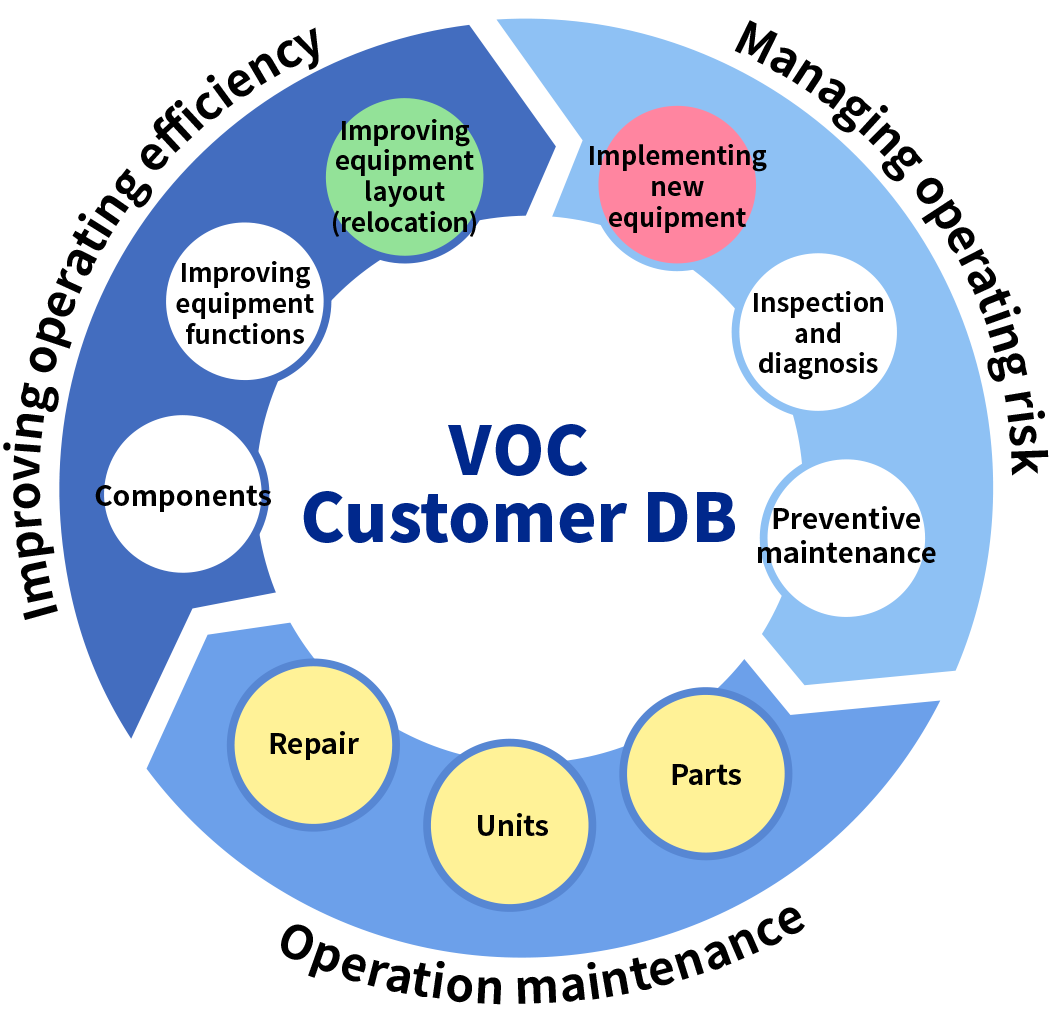

Service business

Offering life-cycle support backed by experience

We offer logistics services ranging from daily customer support to inspection, repair, preventive maintenance proposals, unit updates, and equipment improvement solutions. In addition, we propose services that prioritize the stability of your operations so you can use the implemented systems for a long time.